-

BORPOWER EU GROUPNanotechnology offers key technologies for the 21st century. BORPOWER EU GROUP set off as pioneer in research and development in the field of Nanotechnology with the commitment and involvement of competent scientists and experts in the areas of physics, chemistry and materials research. ...read more →

BORPOWER EU GROUPNanotechnology offers key technologies for the 21st century. BORPOWER EU GROUP set off as pioneer in research and development in the field of Nanotechnology with the commitment and involvement of competent scientists and experts in the areas of physics, chemistry and materials research. ...read more → -

Nanotechnology The term “nano” derives from the Greek “nanos” and means “dwarf” i.e. a person with microsomia. Nano refers to the size unit “one billionth”. Nanotechnology deals with the research, production and application of structures in nanometer range (<100 nm). A nanometer is a billionth of a meter, or a millionth of a millimetre which ...read more →

Nanotechnology The term “nano” derives from the Greek “nanos” and means “dwarf” i.e. a person with microsomia. Nano refers to the size unit “one billionth”. Nanotechnology deals with the research, production and application of structures in nanometer range (<100 nm). A nanometer is a billionth of a meter, or a millionth of a millimetre which ...read more → -

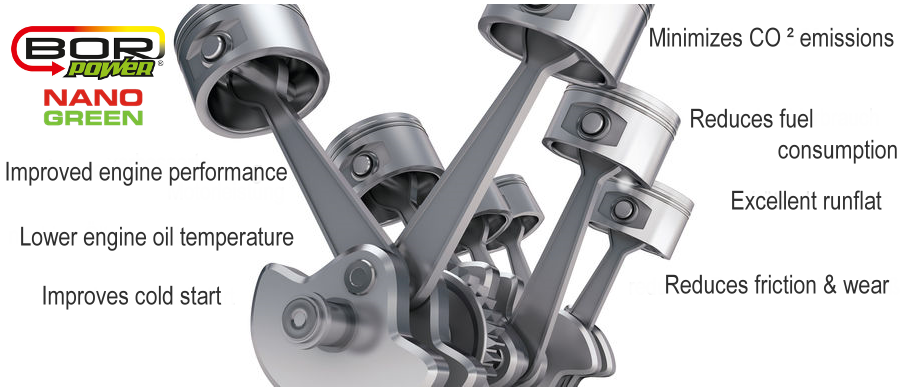

BORPower® Friction, abrasion and corrosion are significant cause for the deterioration of performance and the life time of engines and machines in the private and commercial sector. Moreover, friction is responsible for a reduced efficiency of the machine, which yields increased energy and fuel consumption.BORPower® is...read more →

BORPower® Friction, abrasion and corrosion are significant cause for the deterioration of performance and the life time of engines and machines in the private and commercial sector. Moreover, friction is responsible for a reduced efficiency of the machine, which yields increased energy and fuel consumption.BORPower® is...read more →

Know How

Production of modified nanocrystals from the element boron in the scale of 0,5 to 100 nanometers by means of the “NNT Shock and Detonation Method”. With the special NNT Shock and Detonation Method in the detonation chamber, under a high pressure of up to 170.000 bar and a temperature of 4.300°C, boron nitride is processed through implosion into Mono Crystal Diamond Powder (MCDP) and nanoboron crystals (NBN) in the scale of 0,5 to 100 nanometer; a process lasting 1/1.000.000 seconds. Subsequently, in a refinery, the processed crystals are separated into MCDP, Nanobor, cBN, BN and HBN by using a special filtering technique. These crystals are then solidified using high temperatures in argon furnaces under vacuum exposure until they attain a purity degree of 99.9%. The argon system makes an accelerated homogenization of the modified MCDP and nanoboron crystals possible, in all kinds of fluids with lubricant properties. By means of the process technology described, we obtain base materials to be applied in our products. Moreover, BORPOWER EU GROUP also produces a sustainable amount of high-tech materials for the industrial use and industrial customers. Each level of the production process of MCDP undergoes regular and strict quality controls. Modern methods like x-ray powder diffractometry, electron microscopy and IR spectroscopy are used in our quality control procedures.

read more →BORPower® quality approach

The products of BORPOWER EU GROUP, like the BORPower® product line, are produced in our state-of-the-art facilities and subjected to very strict quality control all the way through the production process. All our products undergo special quality tests during the production process, after the production as well as throughout the entire logistics process. Thus we aim to ensure that each and every product delivered meets the highest standards of quality and reliability and perfectly fulfills its intended function. A well-functioning quality management system in compliance with ISO 9001 is the binding guarantee for our customers and distribution partners.

read more →